Pumps for dangerous liquids:

Chemical industry use a lot of dangerous and toxic products which could have negative effects on humans and their environment.

Compliance with safety, pollution and environmental protection is required.

- PUMPING RESTRICTIONS FOR DANGEROUS LIQUIDS:

Due to the nature of pumped products, external leaks cannot be tolerated.

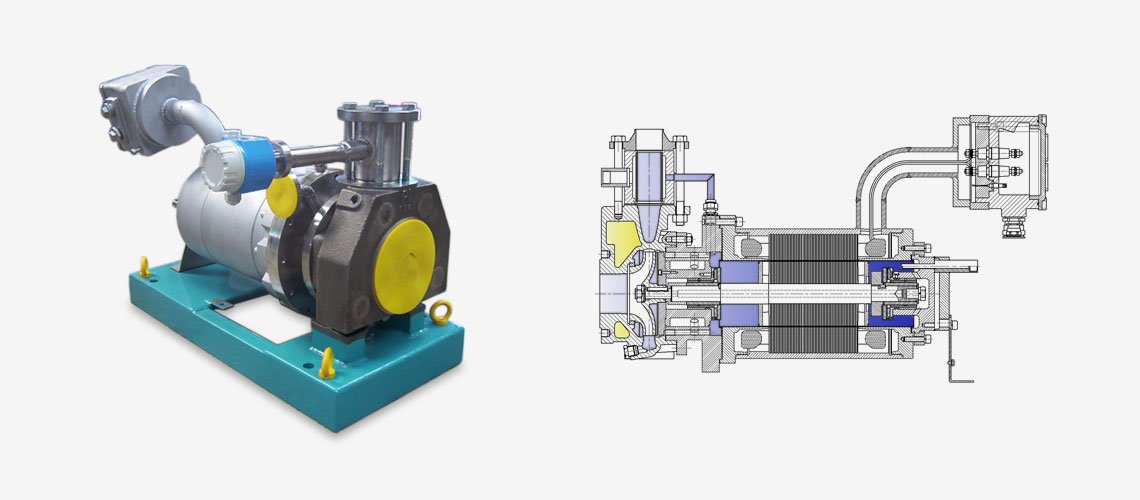

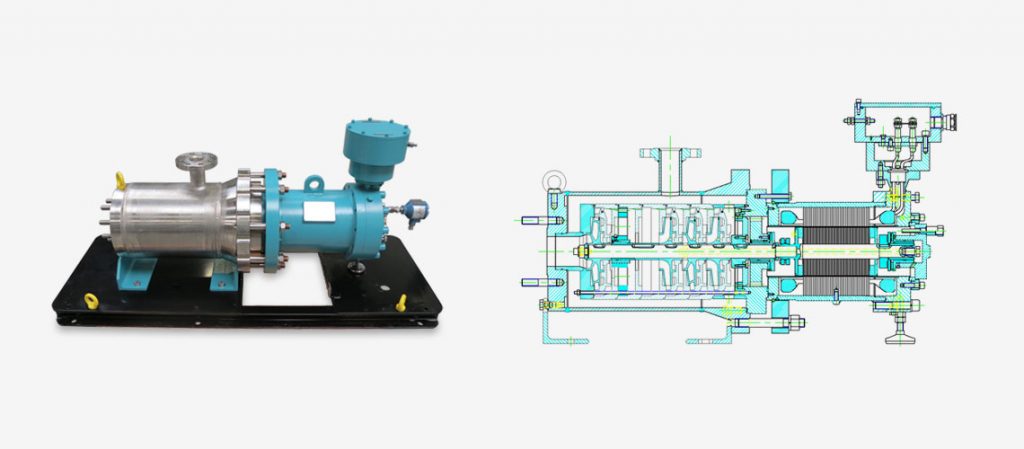

- OPTIMEX SOLUTIONS:

The canned motor pump technology is hermetically sealed due to its monobloc construction without dynamic sealing.

In case of stator liner rupture, the second containment eliminates all risks of leakage to the environment.

Examples of dangerous liquids:

- CMR products (Carcinogenic, Mutagenic, Reprogenic)

- Soda (NaOH)

- Acids (HCl, H2SO4, C₆H₁₀O₄,…)

- Phosgene (COCl2)

- Hydrogen sulfide (H₂S)

- Benzene (C6H6)