Optimex Pumps

SPECIALIST IN THE MANUFACTURE OF SEALLESS PUMPS SINCE 1998

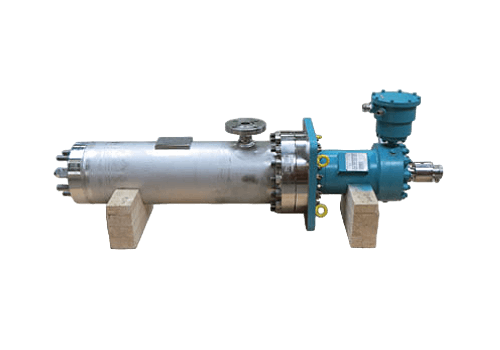

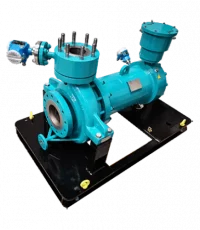

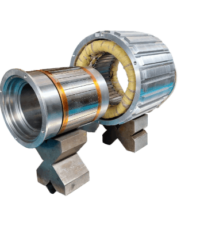

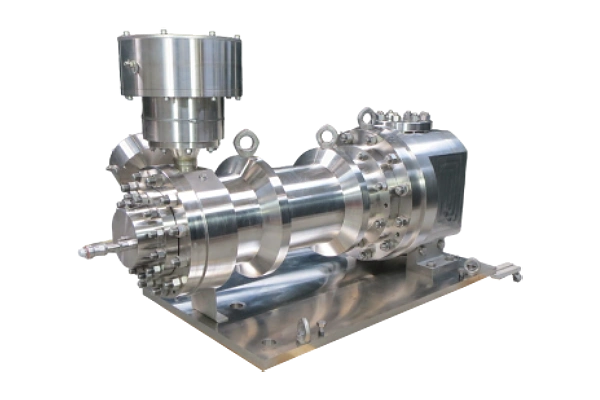

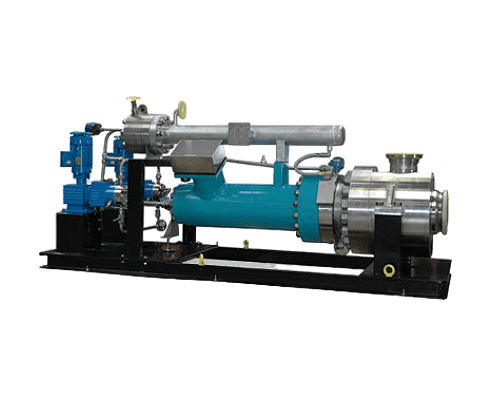

OPTIMEX was founded in 1998 by two passionate mechanics who were determined to develop and manufacture a range of canned motor pumps in France, with the ambition of becoming a key player in this niche market internationally. Initially dedicated to canned motor pumps, and after serving its various customers with innovative, high-quality products, the company has extended its product range to include other sealless technologies such as wet stator pumps and magnetic drive pumps.

Our Key Figures

SEALLESS CENTRIFUGAL PUMP COMPANY

Products

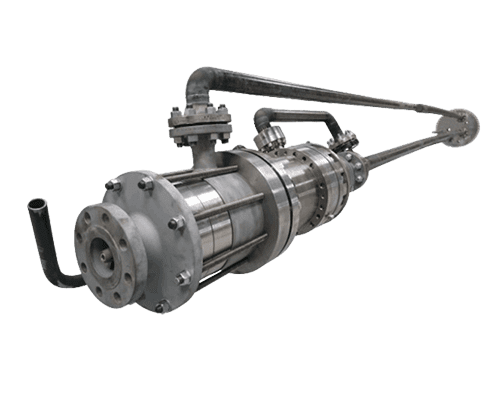

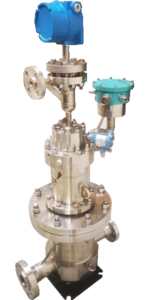

MANUFACTURER OF SEALLESS PUMP

Markets

SEALLESS PUMP FOR INDUSTRIAL MARKETS

Power Generation

+

Optimex sealless pumps are manufactured for various energy markets. Discover the full range of use possible and standards that Optimex meets.

Read moreIndustries

+

Optimex sealless pumps complies with chemical, petrochemical and oil and gas safety applications, especially for critical, toxic and dangerous liquids.

Read moreMarine

+

Optimex offers safe, reliable, discreet and reduced pump solutions for the marine market.

Read moreSpatial

+

Optimex, your trusted partner in the space market, provides high quality and reduced sealless pumps for demanding space applications.

Read moreApplications

SEALLESS PUMP FOR HAZARDOUS LIQUIDS

- Hydrofluoric acid (HF)

- Phosgene (COCl2), triple confinements

- Chlorine (Cl), comply to EuroChlor or Pamphlet 164

Carcinogenic, mutagenic and reprotoxic substances (CMR) liquids are used in several industries. Pumping of these hazardous and toxic products with negative effects on humans and environment.

- LNG (CH4)

- LPG like butane (C4), propane (C3), ethylene (CH2), propene (CH3)

- Carbon dioxide (CO2)

- Hydrogene (H2) or hydrogene liquid (LH2)

Liquefied Petroleum Gas (LPG) is a flammable mixture of hydrocarbon gases, primarily composed of propane and butane. Products is liquid under pressure and evaporates into a gas when released, it is easy to transport and use in various applications.

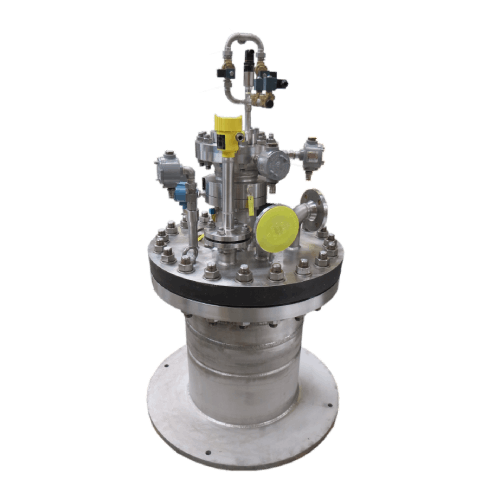

The operation of a nuclear facility necessarily involves the use of radioactive liquids that are hazardous to humans and the environment. OPTIMEX canned motor pumps are particularly well suited to this type of liquid since their double containment and absence of dynamic seals guarantee no risk of leakage.

A canned motor pump is suitable for application with high static suction pressure. To ensure structural integrity and safety, the pump’s design undergoes rigorous stress calculations in accordance with EN standard or CODAP code. Additionally, for compliance with European regulations, a Pressure Equipment Directive (PED) file is carried out.

Somes process with presence of gas, solids or risk of polymerization and crystallization need to be study carrefully. Optimex offers several specific circulations in order to avoid damage the internal parts of the motopump.

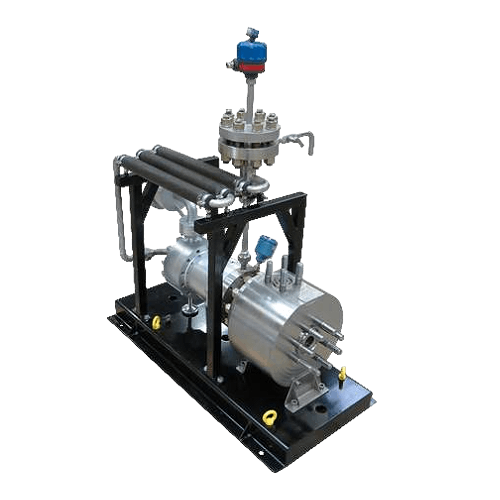

Many industries use hot oils and heat transfer fluid for their process which can generates accidents and fires in case of external leakage . Discover the several solutions proposed by Optimex with specific hot motor, coolers and finned tube to guarantee a safe and reliable operation on site.

In some industrial processes, it is necessary to convey gas or liquids in supercritical phase. In these cases, the fluid requires special pumping constraints and construction need to be adapated.