Installation Phase of OPTIMEX Pumps at Hinkley Point C Nuclear Site

9 July 2025

OPTIMEX at the World Nuclear Exhibition in Paris – WNE 2025

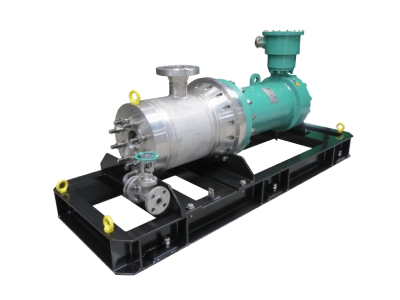

31 October 2025Liquified gas pump for ammonia transfer

MANUFACTURER OF LIQUIFIED GAS PUMP FOR AMMONIA TRANSFER

Sealless Multistage Pump for Hazardous Application in the Fertilizer Industry.

Context and Challenge

A leading phosphate industrial company based in Morocco required a reliable pumping solution to handle liquefied ammonia at -33°C with high pressure transfer.

The pumps were intended for storage operations in a classified explosive area (ATEX), demanding specific safety standards and a leaktight configuration.

Given the hazardous nature of the fluid which can evaporates in contact with atmosphere, the client needed a solution that would combine robust design, safety, and long-term reliability.

Solution Provided by OPTIMEX

OPTIMEX delivered a tailored solution based on its MULTI range of sealless canned motor pumps, specifically designed for liquefied gas applications.

Key features of the solution included:

- Casing barrel design to reduce static seals and anvoid tie rods

- Inducer for improved NPSH performance

- Hermetically sealed pump with no dynamic sealing

- Designed according to API 685 standards

- Compliant with ATEX directive

All six pumps were designed, assembled and tested at OPTIMEX before shipment.

Results and Benefits for the Client

- Safe and leak-free operation in a hazardous environment

- Reliable transfer of liquefied ammonia at low temperature

- Minimal maintenance thanks to Optimex axial balancing system design

- Standardized solution across six units for simplified installation

By providing a safe and efficient pumping solution, OPTIMEX contributed to the secure storage of liquefied ammonia in explosive atmospheres. These multistage pumps with casing barrel reflect OPTIMEX’s expertise in designing tailor-made solutions for critical chemical applications.